Technical parameters / parameters: .table { width: 100%; max-width: 100%; margin-bottom: 1rem; background-color: transparent; } .table td, .table th { padding: .75rem; vertical-align: top; border-top: 1px solid #dee2e6; } Overall dimensions (L,W, H) 1030 х 340 х 580 мм Total weight 190 кг Diameter of the tool 42 мм Capacity не менее 10м³/мин. Internal diameter 20 мм Operating pressure 4 бар - 6 бар Impact energy не менее 1000 дж

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore.jpg" alt="molot_pn_1700-v sbore">

</div>

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore-2.jpg" alt="molot_pn_1700-v sbore-2">

</div>

</div>

<p>Pneumatic hammer (PN) is designed for destruction of rocks, frozen soils, concrete and asphalt pavements, bricks, concrete and reinforced concrete buildings and structures, as well as for soil compaction and installation of light piles, pipes and sheet piles.</p>

<p>It is used in the metallurgical and construction industries./p>

<p><b>Pneumatic hammer characteristics:</b></p>

<style>

.table {

width: 100%;

max-width: 100%;

margin-bottom: 1rem;

background-color: transparent;

}

.table td, .table th {

padding: .75rem;

vertical-align: top;

border-top: 1px solid #dee2e6;

}

</style>

<table class="table">

<tbody>

<tr>

<td >

<p><b>Parameters</b></p>

</td>

<td>

<p><b>PN-1700M4</b></p>

</td>

</tr>

<tr>

<td>

<p>Maximum compressed air pressure, MPa</p>

</td>

<td>

<p>0.7</p>

</td>

</tr>

<tr>

<td>

<p>Operating pressure of compressed air, MPa, maximum</p>

</td>

<td>

<p>0.6</p>

</td>

</tr>

<tr>

<td>

<p>Single impact energy, J</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Impact frequency, min (-1), minimum</p>

</td>

<td>

<p>396</p>

</td>

</tr>

<tr>

<td>

<p>Internal diameter of air hose, mm</p>

</td>

<td>

<p>50</p>

</td>

</tr>

<tr>

<td>

<p><b>Pneumatic hammer characteristics:</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length, mm (without tool)</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Width, mm (connected)</p>

</td>

<td>

<p>420</p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg, without tool/with tool</p>

</td>

<td>

<p>450 / 550</p>

</td>

</tr>

<tr>

<td>

<p><b>Adapter plate dimensions</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length</p>

</td>

<td>

<p>2270</p>

</td>

</tr>

<tr>

<td>

<p>Width</p>

</td>

<td>

<p>520 </p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg </p>

</td>

<td>

<p>400</p>

</td>

</tr>

</tbody>

</table>

<p> </p>

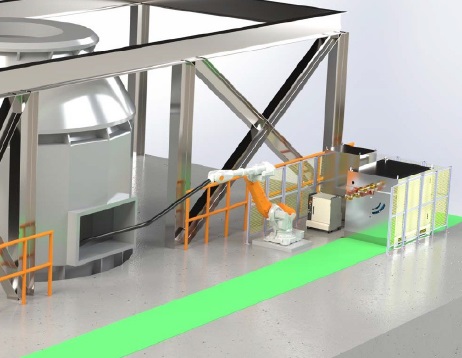

<p>The MATRIX tunable unit is designed for ring laying of refractory lining during repair of rotating furnaces of horizontal type with diameter from 3 m to 7.6 m.</p>

<h2>The benefits of a configurable MATRIX installation are:</h2>

<ul>

<li>reliability of equipment tested for years</li>

<li>ease of use</li>

<li>affordable prices</li>

<li>qualified service from the manufacturer</li>

<li>turnkey project execution</li>

<li>contract supervision</li>

</ul>

<div class="_lightbox row my-0">

<div class="col-sm-6">

<h6 class="my-0 me-3">Download presentation:</h6>

<a class="d-flex me-3" href="/upload/matrix/2.5-4M Russian-3.pdf" target="_blank"><i class="_pdf-ico"></i></a>

</div>

</div>

<h2>Photo gallery:</h2>

<div class="_lightbox row my-5">

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s1.jpg">

<img src="/upload/matrix/matrix_s1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s2.jpg">

<img src="/upload/matrix/matrix_s2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s3.jpg">

<img src="/upload/matrix/matrix_s3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i1.jpg">

<img src="/upload/matrix/i1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i2.jpg">

<img src="/upload/matrix/i2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i3.jpg">

<img src="/upload/matrix/i3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i4.jpg">

<img src="/upload/matrix/i4.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i5.jpg">

<img src="/upload/matrix/i5.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i6.jpg">

<img src="/upload/matrix/i6.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i7.jpg">

<img src="/upload/matrix/i7.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i8.jpg">

<img src="/upload/matrix/i8.jpg" alt="">

</a>

</div>

<!--<div class="col-sm-4">

<a href="/upload/matrix/i9.jpg">

<img src="/upload/matrix/i9.jpg" alt="">

</a>

</div>-->

</div>

Safety, effectiveness and professionalism are our priorities.

Technical parameters / parameters: .table { width: 100%; max-width: 100%; margin-bottom: 1rem; background-color: transparent; } .table td, .table th { padding: .75rem; vertical-align: top; border-top: 1px solid #dee2e6; } Overall dimensions (L,W, H) 1030 х 340 х 580 мм Total weight 190 кг Diameter of the tool 42 мм Capacity не менее 10м³/мин. Internal diameter 20 мм Operating pressure 4 бар - 6 бар Impact energy не менее 1000 дж

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore.jpg" alt="molot_pn_1700-v sbore">

</div>

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore-2.jpg" alt="molot_pn_1700-v sbore-2">

</div>

</div>

<p>Pneumatic hammer (PN) is designed for destruction of rocks, frozen soils, concrete and asphalt pavements, bricks, concrete and reinforced concrete buildings and structures, as well as for soil compaction and installation of light piles, pipes and sheet piles.</p>

<p>It is used in the metallurgical and construction industries./p>

<p><b>Pneumatic hammer characteristics:</b></p>

<style>

.table {

width: 100%;

max-width: 100%;

margin-bottom: 1rem;

background-color: transparent;

}

.table td, .table th {

padding: .75rem;

vertical-align: top;

border-top: 1px solid #dee2e6;

}

</style>

<table class="table">

<tbody>

<tr>

<td >

<p><b>Parameters</b></p>

</td>

<td>

<p><b>PN-1700M4</b></p>

</td>

</tr>

<tr>

<td>

<p>Maximum compressed air pressure, MPa</p>

</td>

<td>

<p>0.7</p>

</td>

</tr>

<tr>

<td>

<p>Operating pressure of compressed air, MPa, maximum</p>

</td>

<td>

<p>0.6</p>

</td>

</tr>

<tr>

<td>

<p>Single impact energy, J</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Impact frequency, min (-1), minimum</p>

</td>

<td>

<p>396</p>

</td>

</tr>

<tr>

<td>

<p>Internal diameter of air hose, mm</p>

</td>

<td>

<p>50</p>

</td>

</tr>

<tr>

<td>

<p><b>Pneumatic hammer characteristics:</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length, mm (without tool)</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Width, mm (connected)</p>

</td>

<td>

<p>420</p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg, without tool/with tool</p>

</td>

<td>

<p>450 / 550</p>

</td>

</tr>

<tr>

<td>

<p><b>Adapter plate dimensions</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length</p>

</td>

<td>

<p>2270</p>

</td>

</tr>

<tr>

<td>

<p>Width</p>

</td>

<td>

<p>520 </p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg </p>

</td>

<td>

<p>400</p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p>The MATRIX tunable unit is designed for ring laying of refractory lining during repair of rotating furnaces of horizontal type with diameter from 3 m to 7.6 m.</p>

<h2>The benefits of a configurable MATRIX installation are:</h2>

<ul>

<li>reliability of equipment tested for years</li>

<li>ease of use</li>

<li>affordable prices</li>

<li>qualified service from the manufacturer</li>

<li>turnkey project execution</li>

<li>contract supervision</li>

</ul>

<div class="_lightbox row my-0">

<div class="col-sm-6">

<h6 class="my-0 me-3">Download presentation:</h6>

<a class="d-flex me-3" href="/upload/matrix/2.5-4M Russian-3.pdf" target="_blank"><i class="_pdf-ico"></i></a>

</div>

</div>

<h2>Photo gallery:</h2>

<div class="_lightbox row my-5">

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s1.jpg">

<img src="/upload/matrix/matrix_s1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s2.jpg">

<img src="/upload/matrix/matrix_s2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s3.jpg">

<img src="/upload/matrix/matrix_s3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i1.jpg">

<img src="/upload/matrix/i1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i2.jpg">

<img src="/upload/matrix/i2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i3.jpg">

<img src="/upload/matrix/i3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i4.jpg">

<img src="/upload/matrix/i4.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i5.jpg">

<img src="/upload/matrix/i5.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i6.jpg">

<img src="/upload/matrix/i6.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i7.jpg">

<img src="/upload/matrix/i7.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i8.jpg">

<img src="/upload/matrix/i8.jpg" alt="">

</a>

</div>

<!--<div class="col-sm-4">

<a href="/upload/matrix/i9.jpg">

<img src="/upload/matrix/i9.jpg" alt="">

</a>

</div>-->

</div>

Safety, effectiveness and professionalism are our priorities.

SAMPLER

Completed more than 20 projects

Starting from 2019 more than 20 projects about automation many factories in Russia and Eastern countries (Egypt, Kingdom of Saudi Arabia, Vietnam, Singapore)

Projects designing

You can apply to us for developing automation projects of any complexity: from design documentation to commissioning.

At presence manual method is used for measuring temperature of the furnace and taking samples in sampling station. But because of high temperature at the sampling station manual method is risky for safety. Moreover, the selection of the results of manual temperature measurement is easily influenced by artificial subjective factors, which can cause instability of measuring results. To solve such issues, we offer implementing of robotic system of automated measuring of temperature and taking samples.

It will increase efficiency of the job and improve working conditions of employees.

Our solutions

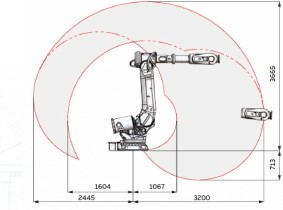

For taking samples and temperature measuring we offer to use six-axles industrial robot, which is flexible in operation and adapts to harsh environmental conditions such as high temperature, noise and dust in the facility, as well as equipped with special protection for robots.

Solution is equipped with a kit for temperature measuring and taking samples from electric-arch furnace at site, it is responsible for automatic temperature measuring and sampling at the station. Main equipment is installed on the platform in front of furnace. Robot can be installed on the left or right side from the working window of the kiln, so robot can input the probe into the furnace quickly after the probe been fixed automatically on the robot. The box for storage the probes is placed on the opposite site of robotic sampler, so the probe is installed and removed from the robot automatically with a measuring gun. The removed probe is put to the box for trash automatically, which stays under the tool for removing and this facilitates access to the site for employees.

Installation of the equipment

Industrial control system

Connection: connection to the PLC, programming of the soft on PLC, modification of parameters, control of interface, work monitoring and another functions. Components: keyboard of Operation System Windows 10, mouse, LCD monitor.

Robotic system

Robotic system is the main executive part of the sampler, which consists of 5 main parts: industrial robot, basement of the robot, quick coupler, accessories for the robot and safety hood for the robot

Main function of the sampler

- Remote control on main pc for automatic temperature measuring and samplings

- Storage function for temperature sensor/sampler

- Automatic sorting of the sensor

- Automatic installation of temperature sensor and sampler

- Unused sensor removing function

- Alarm function for missing material in the sensor box

- Automatic cooling of the gun

- Pause function for sampling

- After the sampling is completed the robot is parked in fixing position

- Staff safety function

- Online monitoring of the system working allows to define the fault

- Automatic measuring data sending to main pc

What do you get from working with us?

solutions

Submit a Request

A modern demolition robot can help you handle many tasks! Demolition robot is an indispensable helper and a real catch for demolition, reconstruction, construction of buildings and structures. Demolition robots are used where large-sized equipment cannot be used.

Customer Service

Prompt response to your requests

Individual approach

Forming an offer to suit your interests

Guaranteed quality

Compliance with quality standards and requirements