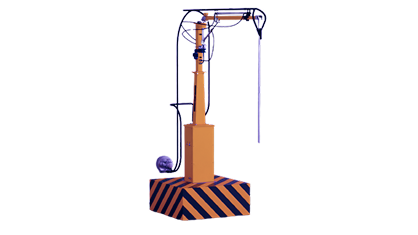

Technical parameters / parameters: .table { width: 100%; max-width: 100%; margin-bottom: 1rem; background-color: transparent; } .table td, .table th { padding: .75rem; vertical-align: top; border-top: 1px solid #dee2e6; } Overall dimensions (L,W, H) 1030 х 340 х 580 мм Total weight 190 кг Diameter of the tool 42 мм Capacity не менее 10м³/мин. Internal diameter 20 мм Operating pressure 4 бар - 6 бар Impact energy не менее 1000 дж

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore.jpg" alt="molot_pn_1700-v sbore">

</div>

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore-2.jpg" alt="molot_pn_1700-v sbore-2">

</div>

</div>

<p>Pneumatic hammer (PN) is designed for destruction of rocks, frozen soils, concrete and asphalt pavements, bricks, concrete and reinforced concrete buildings and structures, as well as for soil compaction and installation of light piles, pipes and sheet piles.</p>

<p>It is used in the metallurgical and construction industries./p>

<p><b>Pneumatic hammer characteristics:</b></p>

<style>

.table {

width: 100%;

max-width: 100%;

margin-bottom: 1rem;

background-color: transparent;

}

.table td, .table th {

padding: .75rem;

vertical-align: top;

border-top: 1px solid #dee2e6;

}

</style>

<table class="table">

<tbody>

<tr>

<td >

<p><b>Parameters</b></p>

</td>

<td>

<p><b>PN-1700M4</b></p>

</td>

</tr>

<tr>

<td>

<p>Maximum compressed air pressure, MPa</p>

</td>

<td>

<p>0.7</p>

</td>

</tr>

<tr>

<td>

<p>Operating pressure of compressed air, MPa, maximum</p>

</td>

<td>

<p>0.6</p>

</td>

</tr>

<tr>

<td>

<p>Single impact energy, J</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Impact frequency, min (-1), minimum</p>

</td>

<td>

<p>396</p>

</td>

</tr>

<tr>

<td>

<p>Internal diameter of air hose, mm</p>

</td>

<td>

<p>50</p>

</td>

</tr>

<tr>

<td>

<p><b>Pneumatic hammer characteristics:</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length, mm (without tool)</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Width, mm (connected)</p>

</td>

<td>

<p>420</p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg, without tool/with tool</p>

</td>

<td>

<p>450 / 550</p>

</td>

</tr>

<tr>

<td>

<p><b>Adapter plate dimensions</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length</p>

</td>

<td>

<p>2270</p>

</td>

</tr>

<tr>

<td>

<p>Width</p>

</td>

<td>

<p>520 </p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg </p>

</td>

<td>

<p>400</p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p>The MATRIX tunable unit is designed for ring laying of refractory lining during repair of rotating furnaces of horizontal type with diameter from 3 m to 7.6 m.</p>

<h2>The benefits of a configurable MATRIX installation are:</h2>

<ul>

<li>reliability of equipment tested for years</li>

<li>ease of use</li>

<li>affordable prices</li>

<li>qualified service from the manufacturer</li>

<li>turnkey project execution</li>

<li>contract supervision</li>

</ul>

<div class="_lightbox row my-0">

<div class="col-sm-6">

<h6 class="my-0 me-3">Download presentation:</h6>

<a class="d-flex me-3" href="/upload/matrix/2.5-4M Russian-3.pdf" target="_blank"><i class="_pdf-ico"></i></a>

</div>

</div>

<h2>Photo gallery:</h2>

<div class="_lightbox row my-5">

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s1.jpg">

<img src="/upload/matrix/matrix_s1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s2.jpg">

<img src="/upload/matrix/matrix_s2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s3.jpg">

<img src="/upload/matrix/matrix_s3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i1.jpg">

<img src="/upload/matrix/i1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i2.jpg">

<img src="/upload/matrix/i2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i3.jpg">

<img src="/upload/matrix/i3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i4.jpg">

<img src="/upload/matrix/i4.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i5.jpg">

<img src="/upload/matrix/i5.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i6.jpg">

<img src="/upload/matrix/i6.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i7.jpg">

<img src="/upload/matrix/i7.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i8.jpg">

<img src="/upload/matrix/i8.jpg" alt="">

</a>

</div>

<!--<div class="col-sm-4">

<a href="/upload/matrix/i9.jpg">

<img src="/upload/matrix/i9.jpg" alt="">

</a>

</div>-->

</div>

Safety, effectiveness and professionalism are our priorities.

Technical parameters / parameters: .table { width: 100%; max-width: 100%; margin-bottom: 1rem; background-color: transparent; } .table td, .table th { padding: .75rem; vertical-align: top; border-top: 1px solid #dee2e6; } Overall dimensions (L,W, H) 1030 х 340 х 580 мм Total weight 190 кг Diameter of the tool 42 мм Capacity не менее 10м³/мин. Internal diameter 20 мм Operating pressure 4 бар - 6 бар Impact energy не менее 1000 дж

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore.jpg" alt="molot_pn_1700-v sbore">

</div>

<div class="col-sm-4">

<img сlass="img-fluid" src="/upload/pnevmolot/v-sbore-2.jpg" alt="molot_pn_1700-v sbore-2">

</div>

</div>

<p>Pneumatic hammer (PN) is designed for destruction of rocks, frozen soils, concrete and asphalt pavements, bricks, concrete and reinforced concrete buildings and structures, as well as for soil compaction and installation of light piles, pipes and sheet piles.</p>

<p>It is used in the metallurgical and construction industries./p>

<p><b>Pneumatic hammer characteristics:</b></p>

<style>

.table {

width: 100%;

max-width: 100%;

margin-bottom: 1rem;

background-color: transparent;

}

.table td, .table th {

padding: .75rem;

vertical-align: top;

border-top: 1px solid #dee2e6;

}

</style>

<table class="table">

<tbody>

<tr>

<td >

<p><b>Parameters</b></p>

</td>

<td>

<p><b>PN-1700M4</b></p>

</td>

</tr>

<tr>

<td>

<p>Maximum compressed air pressure, MPa</p>

</td>

<td>

<p>0.7</p>

</td>

</tr>

<tr>

<td>

<p>Operating pressure of compressed air, MPa, maximum</p>

</td>

<td>

<p>0.6</p>

</td>

</tr>

<tr>

<td>

<p>Single impact energy, J</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Impact frequency, min (-1), minimum</p>

</td>

<td>

<p>396</p>

</td>

</tr>

<tr>

<td>

<p>Internal diameter of air hose, mm</p>

</td>

<td>

<p>50</p>

</td>

</tr>

<tr>

<td>

<p><b>Pneumatic hammer characteristics:</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length, mm (without tool)</p>

</td>

<td>

<p>1700</p>

</td>

</tr>

<tr>

<td>

<p>Width, mm (connected)</p>

</td>

<td>

<p>420</p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg, without tool/with tool</p>

</td>

<td>

<p>450 / 550</p>

</td>

</tr>

<tr>

<td>

<p><b>Adapter plate dimensions</b></p>

</td>

<td>

<p></p>

</td>

</tr>

<tr>

<td>

<p>Length</p>

</td>

<td>

<p>2270</p>

</td>

</tr>

<tr>

<td>

<p>Width</p>

</td>

<td>

<p>520 </p>

</td>

</tr>

<tr>

<td>

<p>Weight, kg </p>

</td>

<td>

<p>400</p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p>The MATRIX tunable unit is designed for ring laying of refractory lining during repair of rotating furnaces of horizontal type with diameter from 3 m to 7.6 m.</p>

<h2>The benefits of a configurable MATRIX installation are:</h2>

<ul>

<li>reliability of equipment tested for years</li>

<li>ease of use</li>

<li>affordable prices</li>

<li>qualified service from the manufacturer</li>

<li>turnkey project execution</li>

<li>contract supervision</li>

</ul>

<div class="_lightbox row my-0">

<div class="col-sm-6">

<h6 class="my-0 me-3">Download presentation:</h6>

<a class="d-flex me-3" href="/upload/matrix/2.5-4M Russian-3.pdf" target="_blank"><i class="_pdf-ico"></i></a>

</div>

</div>

<h2>Photo gallery:</h2>

<div class="_lightbox row my-5">

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s1.jpg">

<img src="/upload/matrix/matrix_s1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s2.jpg">

<img src="/upload/matrix/matrix_s2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/matrix_s3.jpg">

<img src="/upload/matrix/matrix_s3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i1.jpg">

<img src="/upload/matrix/i1.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i2.jpg">

<img src="/upload/matrix/i2.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i3.jpg">

<img src="/upload/matrix/i3.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i4.jpg">

<img src="/upload/matrix/i4.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i5.jpg">

<img src="/upload/matrix/i5.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i6.jpg">

<img src="/upload/matrix/i6.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i7.jpg">

<img src="/upload/matrix/i7.jpg" alt="">

</a>

</div>

<div class="col-sm-4">

<a href="/upload/matrix/i8.jpg">

<img src="/upload/matrix/i8.jpg" alt="">

</a>

</div>

<!--<div class="col-sm-4">

<a href="/upload/matrix/i9.jpg">

<img src="/upload/matrix/i9.jpg" alt="">

</a>

</div>-->

</div>

Safety, effectiveness and professionalism are our priorities.

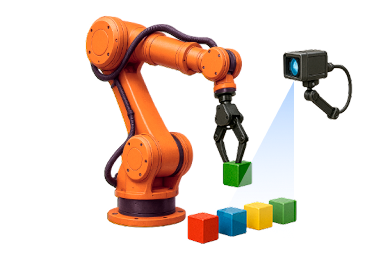

AUTOMATION

FACTORY

Transform your production using robotics and artificial intelligence!Completed more than 20 projects

Starting from 2019 more than 20 projects about automation many factories in Russia and Eastern countries (Egypt, Kingdom of Saudi Arabia, Vietnam, Singapore)

Projects designing

You can apply to us for developing automation projects of any complexity: from design documentation to commissioning.

What we can offer to you?

- Engineering services: developing and designing customized solutions about automation of any industrial sphere

- Technical services: technical analysis of the internal technological process with solutions and recommendations for the introduction of modern equipment.

- Increasing of the quality of products and optimization of technological processes

- Technological equipment: robotics, automated lines, control systems and more. Delivery, installation, maintenance, training.

Industrial automation system

OUR SOLUTIONS

Engineering services: developing and designing customized solutions about automation of any industrial sphere

What do you get from working with us?

solutions

Advantages of introduction robotics for factory automation

Benefits of automation implementation

Submit a Request

A modern demolition robot can help you handle many tasks! Demolition robot is an indispensable helper and a real catch for demolition, reconstruction, construction of buildings and structures. Demolition robots are used where large-sized equipment cannot be used.

Customer Service

Prompt response to your requests

Individual approach

Forming an offer to suit your interests

Guaranteed quality

Compliance with quality standards and requirements